Virtually silent, fully enclosed, Tesla – bladeless wind turbines on the way

High efficiency wind turbine based on jet engine technology

Schooling fish inspire new approach to wind farming – to 10 times more efficient

Reno and Boston Put Wind Turbines on City Hall Roofs

Reno and Boston Put Wind Turbines on City Hall Roofs

Jun 3, 2010, By Russell Nichols, Staff Writer

From the roof of Reno’s City Hall, two 1.5 kilowatt wind turbines designed with special hoops to reduce noise

This week, Reno became one of the first cities in the nation to install windmills on a city hall roof. Two years in the making, this project marks the latest stage in Reno’s ongoing effort to plant small-scale turbines throughout the city to produce energy and save money, said Jason Geddes, the city’s environmental services administrator. The city has already installed a turbine at the sewage plant and one at a park. In total, nine urban turbines are slated to go up, so city officials can test how they perform in various environments.

In the U.S., wind turbines produce enough electricity on a typical day to power the equivalent of more than 9.7 million homes, according to Tom Welch, spokesman for the U.S. Department of Energy (DOE). The DOE leads the nation’s push for enhanced, affordable wind and water power technologies through its Wind and Water Power Program.

Reno officials are betting big money that renewable energy projects will pay off. The city, Geddes said, is investing $1 million for wind programs with a total of about $19 million for new energy technology. With wind, solar and energy-efficiency projects, he added, local officials expect to reduce energy use by 25 percent and save $1 million a year.

None of the investment money is coming out of the city’s general fund. About $4.1 million comes from grants and utility rebates, the rest from stimulus bonds that the city plans to pay back with the money it saves on energy costs, Geddes said.

“It’s a great thing to do to lower energy bills as much as you can,” he said, “and hedge against future increases in fossil fuel energy.”

Winds of Change, Boston, Jacksonville

Reno isn’t the only city to put windmills on city buildings. In 2008, Boston Mayor Thomas M. Menino proposed putting a small-scale windmill on top of City Hall to convert sea breezes into clean energy. By the fall of 2008, the turbine was up and running.

“The wind power demonstration project on City Hall and the potential for turbines on school grounds will showcase the tremendous promise that renewable energy holds in Boston and beyond,” James W. Hunt, Boston’s chief of environment and energy, said in a 2008 release. But, according to The Boston Channel, the windmill stirred controversy due to its limited power and the thousands of dollars it cost taxpayers.

However: Wind spires can save an average of $12,000 to $15,000 a year. They cost about $10,000 to install, and can last up to 25 years.

see Jacksonville, Florida: Wind: Eye-Catching Alternative Energy on Atlantic Blvd

Regardless, proponents see these small-scale turbines as a sign of a greener tomorrow. In Reno, officials plan to use the city’s website to keep the public informed on how wind power works and why it might be a smart investment.

Starting this month, Geddes said, the website will offer real-time data on wind speed, turbine locations and electrical output. By plugging addresses into a 3-D regional map, citizens can gauge typical wind conditions and see how much energy a particular turbine on their property could produce.

“People will be able to look at where they will put a turbine in that region and get an estimate,” Geddes said. “There’s so much new technology in the market. A lot of these systems can work in the urban environment.”

Urban Turbines

The plan to put wind turbines on the roof of Reno City Hall dates back to a yearlong energy audit in 2008. At that time, Geddes said, local officials analyzed ways to incorporate renewable wind and solar projects into the system. “As we were developing that, the stimulus bill passed,” he said. “That gave us the funding we needed to support this project.”

With the city turbines scattered around Reno, officials and manufacturers hope citizens catch wind of the power-producing potential of urban turbines. In July, Windspire, a Reno-based, small-scale wind company, will install one of its propeller-free, vertical turbines on a city-owned parking garage.

“When you talk about wind power, most people think of big turbines in the middle of nowhere,” said Amy Berry, Windspire’s director of marketing. “We’re big proponents of the city putting small wind turbines around because it will introduce more people to the idea of small wind.”

Schooling fish inspire new approach to wind farming – to 10 times more efficient

By Ben Coxworth

17:27 May 18, 2010

Schooling fish, it turns out, have a lot to teach us about setting up wind farms. That’s the conclusion reached by John Dabiri, a fluid dynamics expert from the California Institute of Technology (Caltech). One of the biggest current problems with wind farms is the large land area that they require – if you place the turbines too close to one another, they will be adversely effected by each other’s turbulence. By applying principles learned from observing fish, however, Dabiri thinks he might have found a solution.

First off, he is not using the common type of wind turbine. What we’re used to seeing are horizontal-axis turbines, with the big windmill-style blades that spin in a circle perpendicular to the ground. Dabiri is using vertical-axis turbines, that look not unlike an old-school lawnmower (or combine) reel standing on one end. Because they don’t have big blades sweeping circles in the air, they can be more densely-spaced than horizontal-axis machines.

One of the first things Dabiri noticed with schooling fish was that the vortices left behind individual fish sometimes rotated clockwise, and sometimes counter-clockwise. In traditional wind farms, all the turbines spin in the same direction, so they all generate the same direction of vortex. Based on this observation, he plans on alternating the spinning direction of neighboring turbines, to see if they actually benefit from the alternating vortices.

Dabiri also noticed that the fish and their vortices were arranged in a staircase pattern relative to one another. Again, this runs contrary to most wind farms, where the turbines are placed in neat rows. By conducting a field study incorporating closely-spaced, staggered vertical-axis turbines spinning in alternating directions, he hopes to show just how much more efficient wind power can become. According to Caltech’s computer models, he believes his set up could be up to ten times more efficient than traditional models.

“Our goal is to demonstrate a new technology that enables us to extract significantly more wind energy from a given parcel of land than is currently possible using existing methods,” said Dabiri. “We want to take advantage of constructive aerodynamic interference between closely spaced vertical-axis wind turbines. Our results can potentially make better use of existing wind farms, allow for wind farms to be located closer to urban centers – reducing power transmission costs – and reduce the size of offshore installations.”

High efficiency wind turbine based on jet engine technology

By Paul Evans; 16:31 December 11, 2008

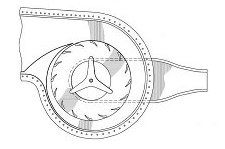

Massachusetts-based FloDesign has developed a wind turbine that could generate electricity at half the cost of conventional wind turbines. The company’s design, which draws on technology developed for jet engines, circumvents a fundamental limit to conventional wind turbines. Typically, as wind approaches a turbine, almost half of the air is forced around the blades rather than through them, and the energy in that deflected wind is lost. At best, traditional wind turbines capture only 59.3 percent of the energy in wind, a value called the Betz limit.

Jet engine wind turbine

FloDesign is a spin-off from the aerospace company FloDesign based in Wilbraham, MA which recently raised $6 million in its first round of venture financing. Their turbine design surrounds its wind-turbine blades with a shroud that directs air through the blades and speeds it up, which increases power production. The shroud concept is based on the same principles as a high bypass jet engine design that is used by all commercial jet aircraft engines to reduce noise and significantly improve efficiency. The new design generates as much power as a conventional wind turbine with blades twice as big in diameter. The smaller blade size and other factors allow the new turbines to be packed closer together in the field compared to conventional turbines, increasing the amount of power that can be generated per acre of land.

From the front, these wind turbine looks something like the air intake of a jet engine. As air approaches, it first encounters a set of fixed blades, called the stator which are common in jet and steam turbines designs used in power generation, which redirect the air onto a set of movable blades, called the rotor. The air turns the rotor and emerges on the other side, moving more slowly now than the air flowing outside the turbine. The shroud is shaped so that it guides this relatively fast-moving outside air into the area just behind the rotors. The fast-moving air speeds up the slow-moving air, creating an area of low pressure behind the turbine blades that sucks more air through them.

Double or triple a turbine’s power output

It’s plausible that such a design could double or triple a turbine’s power output, says Paul Sclavounos, a professor of mechanical engineering at MIT. Part of the increase comes simply from guiding the air to the turbine with the shroud. But Sclavounos notes that it also helps to use the wind surrounding the turbine to speed up the airflow, because the power produced by a wind turbine increases with the cube of the wind speed. The key question is whether the new turbines can be built and maintained at a low-enough cost. A shrouded turbines can be half to a third the size of a conventional 30+ story tall 3 blade turbine for the same power output and with tall towers and blades up to 90 meters long transportation alone can make up to 20% of turbine construction costs so a shrouded turbine may lead to significant reduction in construction costs and as a result cheaper power generation.

It is still early days for the FloDesign turbines as they have only built a small prototype for wind-tunnel tests. Its next step is to build a 12-foot diameter, 10-kilowatt system for field tests. The prototype is expected to be finished by the end of next year or early in 2010, with commercial wind turbines to follow. Eventually the company plans to make turbines as large as one megawatt, but is not yet taking orders.

Virtually silent, fully enclosed, Tesla – bladeless wind turbines on the way

By Karen Sprey; 17:30 May 6, 2010

A wind turbine that uses boundary layers instead of blades to generate power has been patented by Solar Aero, a New Hampshire based not-for-profit scientific research organization. Modeled on the 1913 Tesla steam turbine, the Fuller turbine is virtually silent and completely enclosed, which avoids many of the drawbacks of bladed turbines such as noise, radar interference, visual pollution and wildlife injuries.

Solar Aero’s Howard Fuller says the principal of operation is roughly the same as for the Tesla steam turbine.

“Closely-spaced discs trap the motive fluid molecules (in this case air) in a laminar flow adjacent to the disc surface. This provides aerodynamic drag, which imparts force to the disc surface. By using multiple discs, the turbine then provides considerable torque to accelerate the rotation of the central driveshaft, which is directly coupled to an alternator, typically located at the base of a tower, or alternatively co-located on a rooftop.”

The turbine is likely to have a cut-in speed of about 3.5 knots and optimum speed is about 20 knots and near transparency to radar microwave transmissions can be achieved with proper construction materials and techniques.

Although currently only in pre-prototype stage, it is anticipated that units would be available in different sizes. The smallest unit would be likely to produce about 5kW at 15 knots.

Solar Aero expects costs to be comparable to coal-fired power generation – around $0.05/kWh. When used in conjunction with a suitable storage device, this should provide reliable, inexpensive power in either residential or commercial applications.

Maintenance costs should be less than for bladed turbines. As the up-tower turbine is supported solely on zero maintenance magnetic bearings, there will be no friction to impede acceleration and no routine lubrication required.

Solar Aero is currently completing a full scale prototype. The design will be available for worldwide production licensing following testing.

Contact Solar Aero for further information.

http://www.gizmag.com/bladeless-wind-turbines/14977/

Wind Turbines “www.windturbines.net is positioned to be the largest social network for the wind turbine community where the public and the wind energy profession can come together to get advice, share ideas and network for career advancement.”